Introduction

Research in the Kappe laboratories for the past decade has focused on the use of continuous flow technology for organic synthesis, in particular related to the generation of active pharmaceutical ingredients (APIs). In close coordination with Graz University of Technology (Institute of Process and Particle Engineering) and the COMET K1 Center Research Center Pharmaceutical Engineering GmbH (RCPE) in Graz a long-term strategic plan has been developed to establish an internationally visible and competitive “Center of Excellence” on Flow Chemistry in Graz.

In addition to the nationally funded COMET – K-Project CC FLOW the government of Styria (Zukunftsfonds Steiermark) in 2018 has awarded an infrastructure grant (INFRA FLOW) jointly to the University of Graz (UG) and Graz University of Technology (TUG) aiding in the creation of pioneering flow processing R&D infrastructure that significantly advances the abilities of the Graz flow chemistry team (INFRA FLOW).

Research Objectives

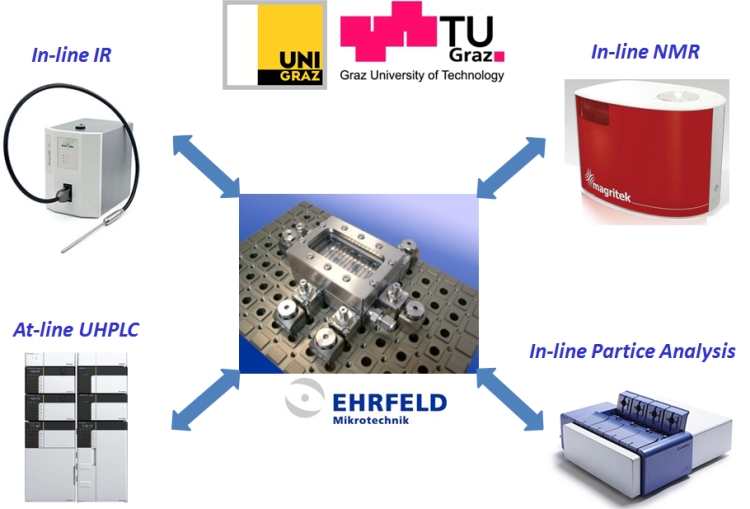

Key component of the new 0.62 Mio € infrastructure is a high-performance modular flow chemistry platform that allows full process automation and intensified flow processing under a wide range of different reaction conditions. A main goal of INFRA FLOW is to directly connect this platform with various in-line (IR, NMR), at-line (UHPLC) reaction monitoring and particle analysis tools which will significantly increase control of product quality, which is one of the major challenges in the manufacturing of pharmaceuticals. The platform not only enables continuous processing on laboratory scale; conditions can be readily transferred to full industrial scale using appropriately designed larger flow reactor devices (direct scalability via smart dimensioning). The integrated flow chemistry/process analytical technology platform will be employed in a variety of research projects in close coordination with activities in CC FLOW, as well as for educational and training purposes for the students of both universities.

Platform Components

- Flow Chemistry Platform: Modular MicroReaction System (MMRS) from Ehrfeld Mikrotechnik. The set-up consists of various microreactors (Lonza FlowPlate® Lab), mixers, heat exchangers and residence time units that can be connected on a single base plate using plug&play principles. Integrated temperature and pressure sensors, mass flow controllers, back pressure regulators, thermostats, pumps, and appropriate control software allow fully automated continuous processing and documentation.

- In-line Fourier-Transform Infrared (FTIR) Reaction Monitoring: Direct in-line reaction monitoring by FTIR spectroscopy on the MMRS platform will be performed using a Mettler-Toledo ReactIR probe system.

- In-line Nuclear Magnetic Resonance (NMR) Reaction Monitoring: Direct in-line reaction monitoring by NMR on the MMRS platform will be performed using a Magritek SPINSOLVE 43 MHz ULTRA benchtop NMR system using a flow cell.

- At-line Ultra-High Performance Liquid Chromatography (UHPLC) Reaction Monitoring: At-line (off-line) reaction monitoring on the MMRS platform will be performed using a Shimadzu Nexera X2 UHPLC system.

- In-line Particle Analysis: Real time particle analysis in continuous flow on the MMRS will be performed with a Crystalline PV from Technobis. The combination of turbidity measurements and particle visualization allows the determination of solubility curves and the detection of particle formation in real-time under process conditions. Direct coupling to Raman spectroscopy furthermore allows the analyses of polymorphism and other chemical characteristics.

While the concurrent integration of IR, NMR and UHPLC techniques into the Ehrfeld flow platform is one dedicated goal of the INFRA FLOW project, the analytical instrumentation acquired within INFRA FLOW will also be interfaced with other flow chemistry equipment available within CC FLOW in order to maximize synergistic effects. Conversely, alternative analytical technology available in Graz (UV, NIR, Raman) will also be interfaced with the Ehrfeld MMRS system if appropriate.

Publication: Laboratory of the Future: A Modular Flow Platform with Multiple Integrated PAT Tools for Multistep Reactions

P. Sagmeister, J. D. Williams, C. A. Hone, C. O. Kappe, React. Chem. Eng. 2019, 4, 1571-1578. DOI: 10.1039/C9RE00087A.

See also publications listed here: SynthesisControl