Flow Chemistry

Traditional manufacturing methods for pharmaceuticals utilizing standard batch-type reactors are currently being challenged globally by more innovative and enabling concepts involving continuous flow processing. This is motivated by the potential of this technology to improve control over quality, reduce costs, enhance sustainability and significantly reduce the timelines currently involved across the drug manufacturing supply chain. Although still at an early stage of development and implementation, continuous chemical processing is seen as key enabling technology for the future of the pharmaceutical manufacturing sector and is therefore strongly supported by regulatory bodies.

In the past few years, continuous-flow reactors with channel dimensions in the micro- or millimeter region have found widespread application in organic synthesis. The characteristic properties of these reactors are their exceptionally fast heat and mass transfer. In microstructured devices of this type virtually instantaneous mixing can be achieved for all but the fastest reactions. Similarly, accumulation of heat, formation of hot-spots and dangers of thermal runaways can be prevented. Owing to the small reactor volumes, the overall safety of the process is significantly improved, even when harsh reaction conditions are applied. Thus, microreactor technology offers a unique way to perform ultrafast, exothermic reactions, and allows the execution of chemistries which proceed via highly unstable or even explosive intermediates. In addition, considerable efforts have been undertaken to devise uninterrupted multistep flow reaction sequences, and elaborate processes for the direct synthesis of complex APIs or intermediates from simple starting materials have been demonstrated.

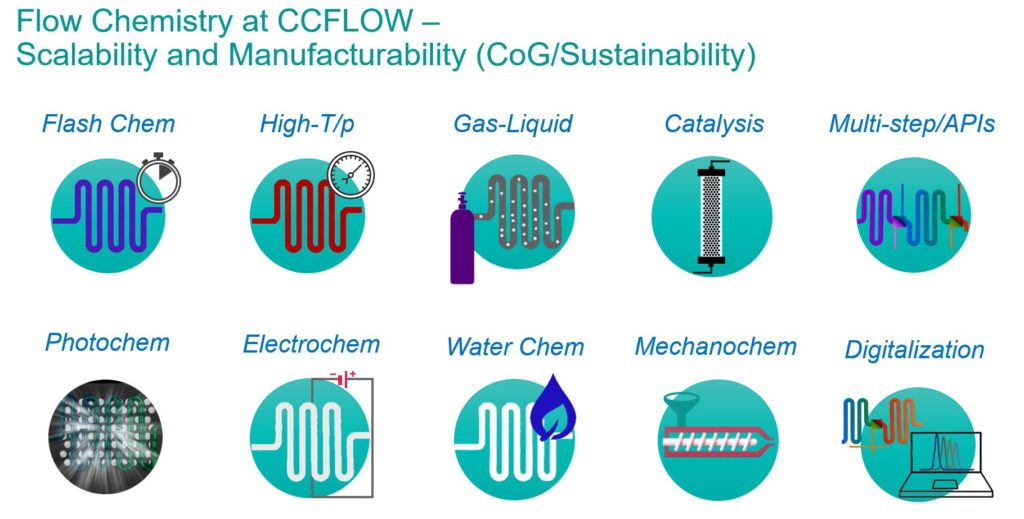

For the past decade the focus of the Kappe laboratory has been directed towards flow chemistry/microreaction technology, encompassing a wide variety of synthetic transformations and experimental techniques. Notably, these include handling hazardous, toxic and/or unstable reagents and gases in flow environments, many times in extreme temperature and pressure regimes reaching the near- or supercritical state. Flow processing has been executed both in monophasic or multiphasic (i.e., liquid/liquid, solid/liquid, gas/liquid, gas/liquid/solid) flow regimes using a range of reactor designs, and utilizing membrane separation techniques, particularly towards the multistep synthesis of APIs. The group additionally has experience in PAT, machine learning/AI, and flow photochemistry/electrochemistry applications. Most recent applications involve the use of slurries in flow reactors.

Many of the above-mentioned flow chemistry projects have been performed in close collaboration between chemists, chemical engineers and process chemists, involving both academic and industrial partners. These endeavors have resulted in ~250 publications (and several patents) in the past decade, many of them in collaboration with industrial partners.

Key Review Articles

Towards the Standardization of Flow Chemistry Protocols for Organic Reactions

C. A. Hone, C. O. Kappe, Chem. Methods 2021, 1, 454–467.

The Concept of ”Chemical Generators”: On-Site On-Demand Production of Hazardous Reagents in Continuous Flow

D. Dallinger, B. Gutmann, C. O. Kappe, Acc. Chem. Res. 2020, 53, 6688-6729.

Continuous-Flow Technology—A Tool for the Safe Manufacturing of Active Pharmaceutical Ingredients

B. Gutmann, D. Cantillo, C. O. Kappe, Angew. Chem. Int. Ed. 2015, 54, 1330-1341.

Why Flow Means Green – Evaluating the Merits of Continuous Processing in the Context of Sustainability

D. Dallinger, C. O. Kappe, Curr. Opin. Green Sust. Chem. 2017, 7, 6-12.

The Use of Molecular Oxygen in Pharmaceutical Manufacturing – Is Flow the Way to Go?

C. Hone, D. Roberge, C. O. Kappe, ChemSusChem 2017, 10, 32-41.