Forbidden Chemistries

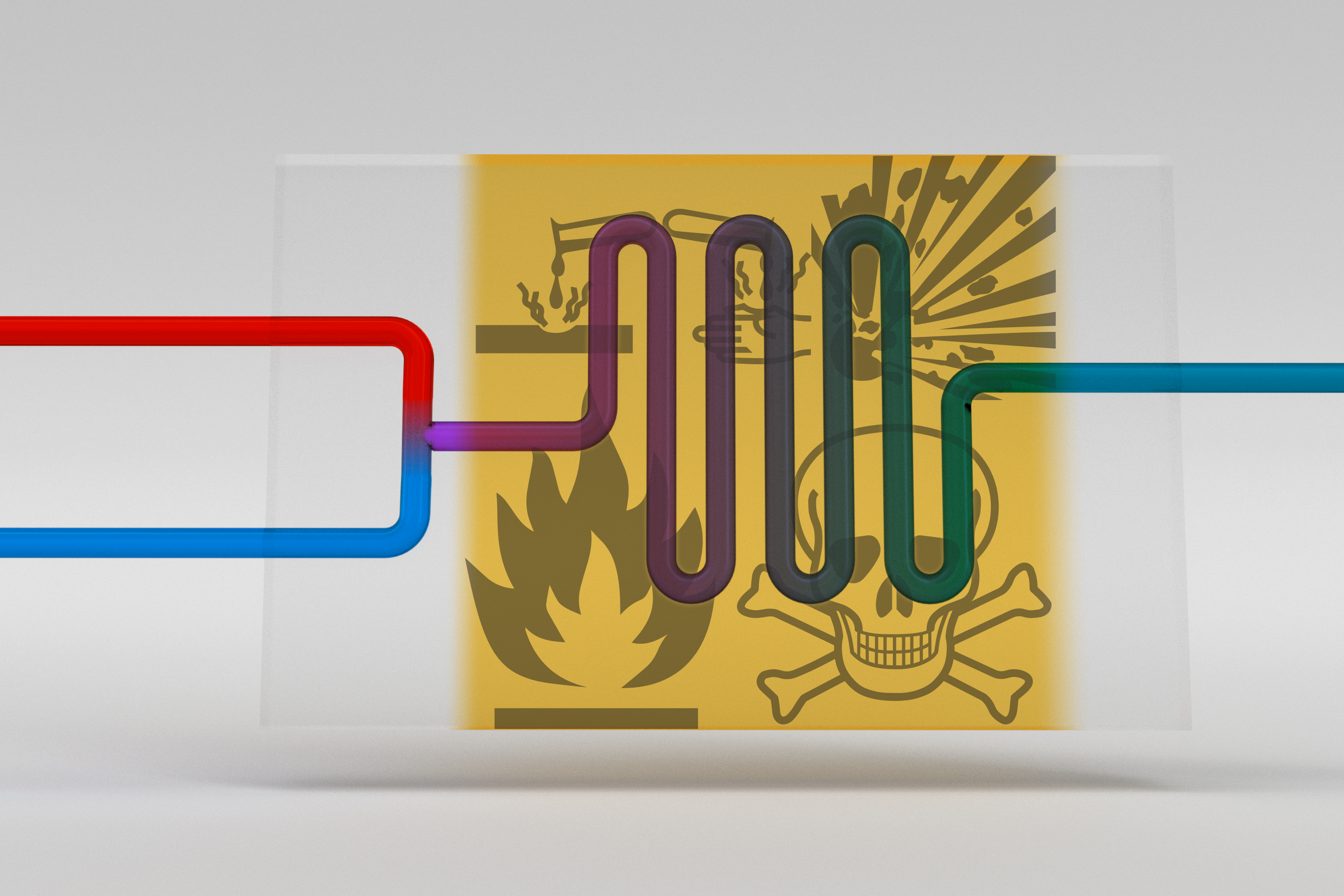

Flow chemistry is typically performed in milli- or microreactors. Microreactors are devices with inner dimensions of the order of one or below one millimeter in size. While tank reactors with volumes of tens of cubic meters are common in chemical companies, the internal volumes of microreactors typically range from below 1 mL to a couple of liters for large reactors. The compact size of microreactors facilitates the control of process parameters, such as reaction temperature, pressure and reaction time (residence time). Furthermore, since the total volume of material processed at any time is drastically reduced, the safety of the process is generally significantly increased compared to the batch counterpart. These aspects make microreactors particularly suited for “hazardous” chemistries such as reactions involving toxic, unstable or explosive intermediates. These intermediates can be generated from benign precursors inside the closed, pressurized environment of the microreactor and subsequently directly converted to a more advanced, nonhazardous product by feeding in multiple reagent streams and manipulating reaction conditions along the reaction path. Therefore, reactions previously impractical (“forgotten chemistry”) or virtually impossible (“forbidden chemistry”) to perform can be operated safely in these devices with little risk at various scales. Our laboratories have extensive experience in handling hazardous chemistry under continuous flow conditions, including toxic/explosive gases.

Key Publications

Review: The Concept of ”Chemical Generators”: On-Site On-Demand Production of Hazardous Reagents in Continuous Flow

D. Dallinger, B. Gutmann, C. O. Kappe, Acc. Chem. Res. 2020, 53, 1330-1341. DOI: 10.1021/acs.accounts.0c00199

Review: Continuous-Flow Technology—A Tool for the Safe Manufacturing of Active Pharmaceutical Ingredients

B. Gutmann, D. Cantillo, C. O. Kappe, Angew. Chem. Int. Ed. 2015, 54, 6688-6729. DOI: 10.1002/anie.201409318

Review: Forbidden Chemistries – Paths to a Sustainable Future Engaging Continuous Processing

B. Gutmann, C. O. Kappe, J. Flow. Chem. 2017, 7, 65-71. https://doi.org/10.1556/1846.2017.00009

Review: Enabling Technologies for Diazomethane Generation and Transformation

D. Dallinger, C. O. Kappe, Aldrichim. Acta 2016, 49, 57-66.

HCN on Tap: On-Demand Continuous Production of Anhydrous HCN for Organic Synthesis

M. Köckinger, C. A. Hone, C. O. Kappe, Org. Lett. 2019, 21, 5326-5330. DOI: 10.1021/acs.orglett.9b01941 .

Integration of Bromine and Cyanogen Bromide Generators for the Telescoped Continuous Synthesis of Cyclic Guanidines

G. Glotz, R. Lebl, D. Dallinger, C. O. Kappe, Angew. Chem. Int. Ed. 2017, 56, 13786–13789. DOI: 10.1002/anie.201708533 .

A Laboratory-Scale Continuous Flow Chlorine Generator for Organic Synthesis

F. J. Strauss, D. Cantillo, J. Guerra, C. O. Kappe, React. Chem. Eng. 2016, 1, 472-476. DOI; 10.1039/c6re00135a. (highlighted by Chemistry World)

Batch and Continuous Flow Aerobic Oxidation of 14-Hydroxy Opioids to 1,3-Oxazolidines – A Concise Synthesis of Noroxymorphone (Hot Paper)

B. Gutmann, U. Weigl, D. P. Cox, C. O. Kappe, Chem. Eur. J. 2016, 22, 10393–10398. DOI:10.1002/chem.201601902

Safe Generation and Use of Bromine Azide under Continuous Flow Conditions ̶ Selective 1,2-Bromoazidation of Olefines

D. Cantillo, B. Gutmann, C. O. Kappe, Org. Biomol. Chem. 2016, 14, 853-857. DOI: 10.1039/c5ob02425k

Development of a Continuous Flow Sulfoxide Imidation Protocol Using Azide Sources under Superacidic Conditions

B. Gutmann, P. Elsner, A. O’Kearney-McMullan, W. Goundry, D. M. Roberge, C. O. Kappe, Org. Process Res. Develop. 2015, 19, 1062-1067. DOI: 10.1021/acs.oprd.5b00217

Singlet Oxygen Oxidation of 5-Hydroxymethylfurfural (5-HMF) in Continuous Flow.

T. S. A. Heugebaert, C. V. Stevens, C. O. Kappe, ChemSusChem 2015, 8, 1648-1651. DOI: 10.1002/cssc.201403182

A Sequential Nitration/Hydrogenation Protocol for the Synthesis of Triaminophloroglucinol − Safe Generation and Use of an Explosive Intermediate under Continuous Flow Conditions

D. Cantillo, M. Damm, D. Dallinger, M. Bauser, M. Berger, C. O. Kappe, Org. Process Res. Develop. 2014, 18, 1360-1366. DOI: 10.1021/op5001435

In Situ Generation of Diimide from Hydrazine and Oxygen – Transfer Hydrogenation of Olefins in Continuous Flow.

B. Pieber, S. T. Martinez, D. Cantillo, C. O. Kappe, Angew. Chem. Int. Ed. 2013, 52, 10241-10244. DOI: 10.1002/anie.201303528

Continuous Flow Generation and Reactions of Anhydrous Diazomethane Using a Teflon AF 2400 Tube-in-Tube Reactor.

F. Mastronardi, B. Gutmann, C. O. Kappe, Org. Lett. 2013, 16, 5590-5593. DOI: 10.1021/ol4027914 (covered by „In the Pipeline“ Blog)

Continuous Flow Synthesis of Adipic Acid from Cyclohexene Using Hydrogen Peroxide in High-Temperature Explosive Regimes.

M. Damm, B. Gutmann, C. O. Kappe, ChemSusChem 2013, 6, 978-982. DOI: 10.1002/cssc.201300197

Synthesis of 5-Substituted 1H-Tetrazoles from Nitriles and Hydrazoic Acid Using a Safe and Scalable High-Temperature Microreactor Approach.

B. Gutmann, J.-P. Roduit, D. Roberge, C. O. Kappe, Angew. Chem. Int. Ed. 2010, 49, 7101-7105. DOI: 10.1002/anie.201003733