Extreme Process Windows

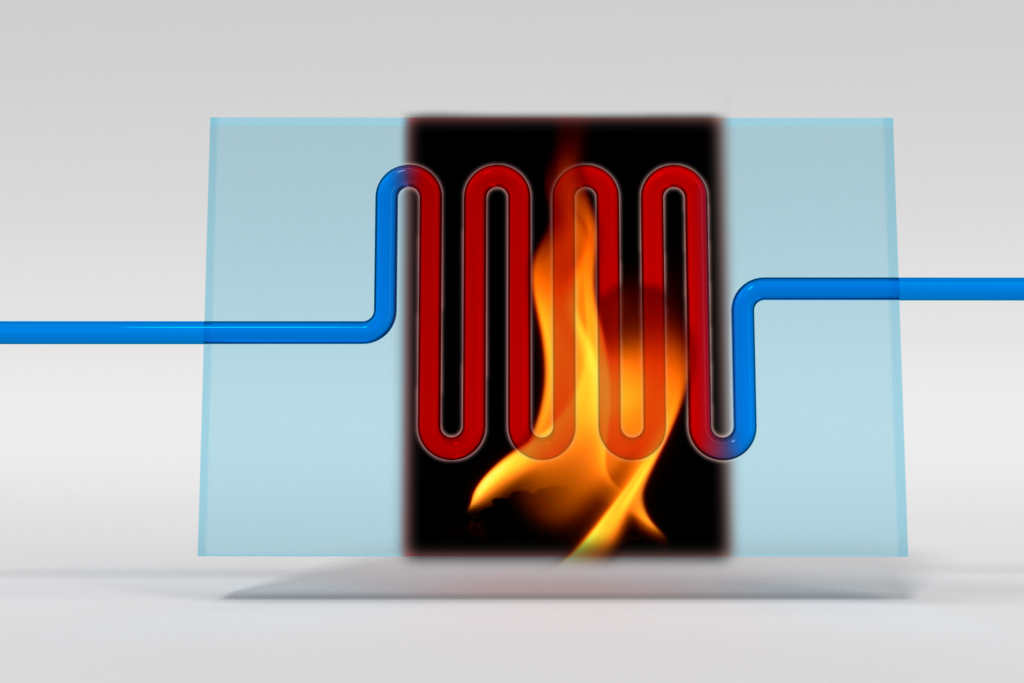

In flow chemistry elevated temperatures and pressures can readily be employed to increase the reaction rate applying back pressure regulators. The reaction rate usually depends roughly exponentially on temperature and increasing the reaction temperature is often the easiest and most effective way to enhance reactivity. Temperatures above around 200 °C are largely outside the operation range of most conventional tank reactors in the pharmaceutical industry. Furthermore, for batch reactions the whole installation has to be heated to the target temperature and cooled after the reaction is finished. In contrast, for flow processes only the reaction mixture is heated while it is carried through the channels of a flow reactor at constant temperature, and the processed mixture is subsequently cooled in a heat exchanger at constant temperature. Combined with the rapid heat exchange capability of microreactors, extremely efficient and responsive heating is thus attained. Furthermore, the small dimensions of microreactors entail high resistance to pressure. As a result, temperatures far above the atmospheric boiling point of the solvent become accessible fairly easily and safely. Higher reaction rates, in turn, yield higher throughputs or allow a further reduction of the reactor size and consequently reactor cost. Since the advent of batch microwave reactors around 30 years ago it became obvious that a wide range of diverse chemical transformations are very amenable to high temperature processing. Continuous flow microreactors now provide the technology necessary to scale these reactions up to industrially relevant scales. The Kappe laboratory has published extensively on high temperature/pressure flow chemistry and the translation of batch microwave into scalable flow protocols.

Key Publications

Review: The Microwave-to-Flow Paradigm: Translating High-Temperature Batch Microwave Chemistry to Scalable Continuous Flow Processes.

T. N. Glasnov, C. O. Kappe, Chem. Eur. J. 2011, 17, 11956-11968. DOI: 10.1002/chem.201102065

Review: Continuous Flow Organic Synthesis Under High Temperature/Pressure Conditions.

T. Razzaq, C.O. Kappe, Chem. Asian J. 2010, 5, 1274-1289. DOI: 10.1002/asia.201000010

Scalable Wolff-Kishner Reductions in Extreme Process Windows Using a Silicon Carbide Flow Reactor

D. Znidar, A. O´Kearney-McMullan, R. Munday, C. Wiles, P. Poechlauer, C. Schmoelzer, D. Dallinger, C. O. Kappe, Org. Process Res. Dev. 2019, 23, 2445-2455. DOI: 10.1021/acs.oprd.9b00336.

Development of a Continuous-Flow Process for a Pd-Catalyzed Olefin Cleavage using Oxygen within the Explosive Regime

C. Hone, A. O’Kearney-McMullan, R. Munday, C. O. Kappe, ChemCatChem 2017, 9, 3298 – 3302. DOI: 10.1002/cctc.201700671.

Continuous Synthesis of Hydantoins: Intensifying the Bucherer-Bergs Reaction

J. L. Monteiro, B. Pieber, A. G. Corrêa, C. O. Kappe, Synlett 2016, 27, 83-87. DOI: 10.1055/s-0035-1560317

Process Intensified Flow Synthesis of 1H-4-Substituted Imidazoles: Toward the Continuous Production of Daclatasvir

P. F. Carneiro, B. Gutmann, R. O. M. A. de Souza, C. O. Kappe, ACS Sust. Chem. Eng. 2015, 3, 3445−3453. DOI: 10.1021/acssuschemeng.5b01191

Direct Preparation of Nitriles from Carboxylic Acids in Continuous Flow.

D. Cantillo, C. O. Kappe, J. Org. Chem. 2013, 78, 10567-10571. DOI: 10.1021/jo401945r

Continuous Flow Synthesis of n-Alkyl Chlorides in a High-Temperature Microreactor Environment.

B. Reichart, G. Tekautz, C. O. Kappe, Org. Process Res. Develop. 2013, 17, 152-156. DOI: 10.1021/op300273u

In Situ Generated Iron Oxide Nanocrystals as Efficient and Selective Catalysts for the Reduction of Nitroarenes in Continuous Flow.

D. Cantillo, M. Baghbanzadeh, C. O. Kappe, Angew. Chem. Int. Ed. 2012, 51, 10190-10193. DOI: 10.1002/anie.201205792

Microwave-assisted Continuous Flow Synthesis on Industrial Scale.

R. Morschhäuser, M. Krull, C. Kayser, C. Boberski, R. Bierbaum, P. A. Püschner, T. N. Glasnov, C. O. Kappe, Green Process. Synthesis 2012, 1, 281-290. DOI 10.1515/gps-2012-0032

Methylation Using Dimethylcarbonate Catalysed by Ionic Liquids Under Continuous Flow Conditions.

T. N. Glasnov, J. D. Holbrey, C. O. Kappe, K. R. Seddon, T. Yan, Green Chem. 2012, 14, 3071-3076. DOI: 10.1039/c2gc36226k

Flash Flow Pyrolysis: Mimicking Flash Vacuum Pyrolysis in a High-Temperature/High-Pressure Liquid-Phase Microreactor Environment.

D. Cantillo, H. Sheibani, C. O. Kappe, J. Org. Chem. 2012, 77, 2463-2473. DOI: 10.1021/jo3001645

Translating High-Temperature Microwave Chemistry to Scalable Continuous Flow Processes.

M. Damm, T. N. Glasnov, C. O. Kappe, Org. Process Res. Develop. 2010, 14, 215-224. DOI: 10.1021/op900297e