Catalysis in Flow

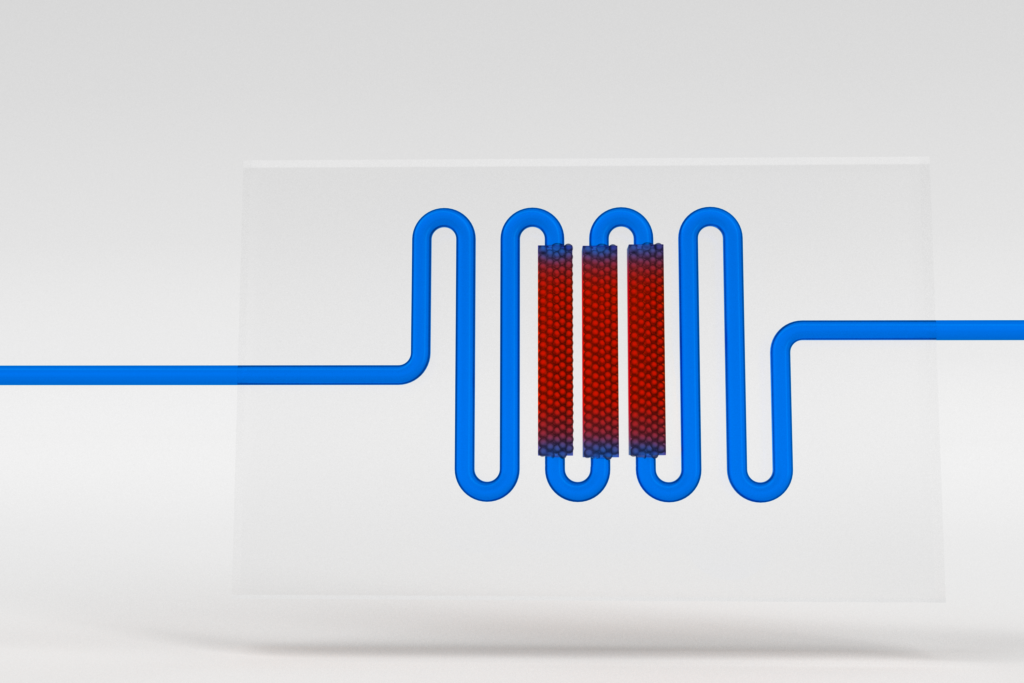

In a continuous flow process a catalyst is often placed in a packed bed reactor and the reaction mixture is flown through the reactor using appropriate pumping systems. The catalytically active material remains located in a specific part of the reactor during processing of the reaction mixture. In this way, reaction and separation of the catalyst from the solution (including the product) take place simultaneously, thus enormously simplifying catalyst re-use and recycling as a catalyst separation/filtration step can be avoided. The reaction mixture flows through the packed catalyst bed, leading to a very high ratio between the active catalyst and the substrates/reagents. This high local concentration of catalyst, combined with the enhanced mass transfer in a microreactor results in increased reaction rates and higher turnover numbers (TONs) as compared to a batch reaction, especially in these cases where the mass transfer has a limiting effect. The most prominent examples involving heterogeneous catalysis in combination with continuous flow processing are transition metal-catalyzed hydrogenation reactions, In these transformations very efficient gas–liquid–solid (reagent-substrate-catalyst) interactions take place due to the large interfacial areas and the short diffusion paths in the packed columns, while in batch the mixing between the three phases is usually poor. The Kappe laboratory has worked extensively in the field of catalytic flow hydrogenations and Pd-catalyzed cross-couplings using both heterogeneous and homogeneous catalysts. We also have an interest in nano-, photoredox- and organocatalysis under continuous flow conditions.

Key Publications

Review: Immobilized Transition Metals as Catalysts for Cross-Couplings in Continuous Flow – A Critical Assessment of the Reaction Mechanism and Metal Leaching.

D. Cantillo, C. O. Kappe, ChemCatChem 2014, 6, 3286-3305. DOI: 10.1002/cctc.201402483

Review: Heterogeneous Catalytic Hydrogenation Reactions Using Continuous Flow Reactors.

M. Irfan, T. N. Glasnov, C. O. Kappe, ChemSusChem, 2011, 4, 300-316. DOI: 10.1002/cssc.201000354

Scalable Continuous Flow Hydrogenations Using Pd/Al2O3-coated Rectangular Cross-section 3D-printed Static Mixers

R. Lebl, Y. Zhu, D. Ng, C. Hornung, D. Cantillo, C. O. Kappe Catal. Today. 2022, 338, 55-63. DOI: 10.1016/j.cattod.2020.07.046.

Multigram-Scale Flow Synthesis of the Chiral Key Intermediate of (–)-Paroxetine Enabled by Solvent-Free Heterogeneous Organocatalysis

S. B. Ötvös, M. A. Pericas, C. O. Kappe, Chem. Sci. 2019, 10, 11141-11146. DOI: 10.1039/C9SC04752B.

Continuous Flow Synthesis of Carbonylated Heterocycles via Pd-Catalyzed Oxidative Carbonylation Using CO and O2 at Elevated Temperature and Pressure

Y. Chen, C. A. Hone, B. Gutmann, C. O. Kappe, Org. Process Res. Dev. 2017, 21, 1080-1087. DOI: 10.1021/acs.oprd.7b00217.

Development of a Continuous-Flow Sonogashira Cross-Coupling Protocol using Propyne Gas under Process Intensified Conditions

D. Znidar, C. Hone, P. Inglesby, A. Boyd, C. O. Kappe, Org. Process Res. Dev. 2017, 21, 878-884. DOI: 10.1021/acs.oprd.7b00160.

Development of a Continuous-Flow Process for a Pd-Catalyzed Olefin Cleavage using Oxygen within the Explosive Regime

C. Hone, A. O’Kearney-McMullan, R. Munday, C. O. Kappe, ChemCatChem 2017, 9, 3298 – 3302. DOI: 10.1002/cctc.201700671.

Continuous Flow Synthesis of Indoles by Pd-catalyzed Deoxygenation of 2-Nitrostilbenes with Carbon Monoxide

G. Glotz, B. Gutmann, P. Hanselmann, A. Kulesza, D. Roberge, C. O. Kappe, RSC Adv. 2017, 7, 10469-10478. DOI: 10.1039/c7ra01087g.

Benchmarking Immobilized Di- and Triarylphosphine Palladium Catalysts for Continuous Flow Cross-Coupling Reactions: Efficiency, Durability and Metal Leaching Studies

R. Greco, W. Goessler, D. Cantillo, C. O. Kappe, ACS Catalysis 2015, 5, 1303-1312. DOI: 10.1021/cs5020089

Continuous Flow Preparation of Supported Iron Oxide Nanoparticles on Porous Silicates

A. Yepez, F. L.Y. Lam, A. A. Romero, C. O. Kappe, R. Luque, ChemCatChem 2015, 7, 276–282. DOI: 10.1002/cctc.201402802

Shifting Chemical Equilibria in Flow – Efficient Decarbonylation Chemistry Driven by Annular Flow Regimes.

B. Gutmann, P. Elsner, T. Glasnov, D. M. Roberge, C. O. Kappe, Angew. Chem. Int. Ed. 2014, 53, 11557-11561. DOI: 10.1002/anie.201407219

Immobilized Iron Oxide Nanoparticles as Stable and Reusable Catalysts for Hydrazine-mediated Nitro Reductions in Continuous Flow

M. Mirhosseini Moghaddam, B. Pieber, T. Glasnov, C. O. Kappe, ChemSusChem 2014, 7, 3122-3131. DOI: 10.1002/cssc.201402455

Nanocatalysis in Continuous Flow: Supported Iron Oxide Nanoparticles for the Heterogeneous Aerobic Oxidation of Benzyl Alcohol.

D. Obermayer, A. M. Balu, A. A. Romero, W. Goessler, R. Luque, C. O. Kappe, Green Chem. 2013, 15, 1530-1537. DOI: 10.1039/c3gc40307f

In Situ Generated Iron Oxide Nanocrystals as Efficient and Selective Catalysts for the Reduction of Nitroarenes in Continuous Flow.

D. Cantillo, M. Baghbanzadeh, C. O. Kappe, Angew. Chem. Int. Ed. 2012, 51, 10190-10193. DOI: 10.1002/anie.201205792

Mechanistic Insights Into Copper(I)-Catalyzed Azide-Alkyne Cycloadditions Using Continuous Flow Conditions.

M. Fuchs, W. Goessler, C. Pilger, C. O. Kappe, Adv. Synth. Catal. 2010, 352, 323-328. DOI: 10.1002/adsc.200900726

Continuous Flow Hydrogenation of Functionalized Pyridines.

M. Irfan, E. Petricci, T. N. Glasnov, M. Taddei, C. O. Kappe, Eur. J. Org. Chem. 2009, 1326-1334. DOI: 10.1002/ejoc.200801131

Heterogeneous Versus Homogeneous Palladium Catalysts for Ligandless Mizoroki-Heck Reactions. A Comparison of Batch/Microwave and Continuous Flow Processing.

T. N. Glasnov, S. Findenig, C. O. Kappe, Chem. Eur. J. 2009, 15, 1001-1015. DOI: 10.1002/chem.200802200

Palladium(0) Nanoparticles on Glass-Polymer Composite Materials as Recyclable Catalysts: A Comparison Study on Their Use in Batch and Continuous Flow Processes.

K. Mennecke, R. Cecilia, T. N. Glasnov, S. Gruhl, C. Vogt, A. Feldhoff, M. A. L. Vargas, C. O. Kappe, U. Kunz, A. Kirschning, Adv. Synth. Catal. 2008, 350, 717-730. DOI: 10.1002/adsc.200700510